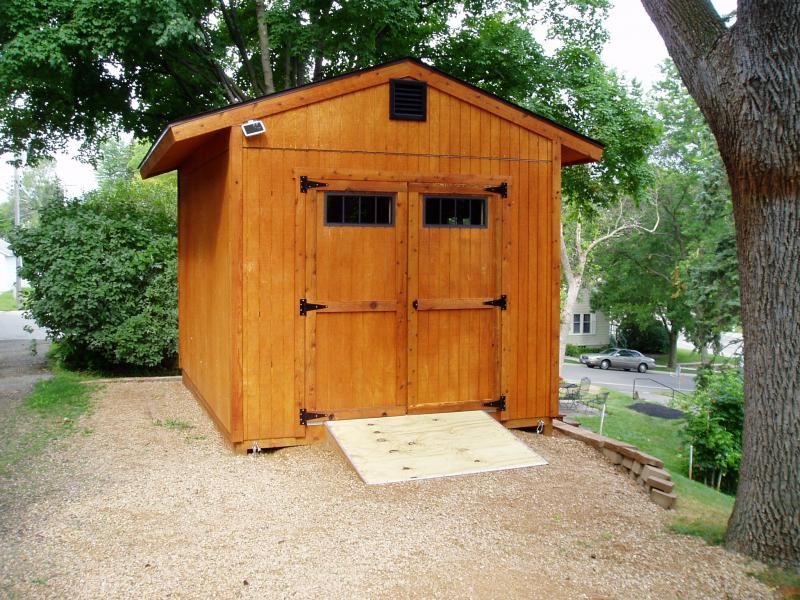

This beautiful 10×14 Gable Shed was built in Bloomington, MN. I has had a few modifications. This is what the owner says about the shed.

Just thought I’d drop you a note and let you know that my son-in-law and I finished the shed. Started on 7/9 and finished on 8/8, so about 4 weeks.

We made a few modifications to the plans. The biggest one is that we went with longer rafter tails as we needed to have the drip line be a certain distance away from the shed. This required us to use something different for the soffit, so we used the same rough sawn plywood that we used for the siding. Another big change is that we went with full 8′ studs in the walls to give maximum interior height. As I’m sure you know, this means that the sidewalls had to be pieced together above the 8′ mark. We inserted blocking between the studs as a backing for the z-channel we used. We kept the upper level siding 1/8″ above the z-channel so it didn’t sit in water. We modified the end rafters so that we could put in a square gable vents. And since I tend to overbuild, all of the rafters were secured with hurricane ties (Simpson H10AZ) and I used twice as many A23’s as the [plans called for (including some to hold the end rafters in place). The floor is ¾” tongue and groove treated plywood. The building inspector said we had to tie the shed down at 4 points, so we used 30″ auger stakes at each corner and tied them with steel cable to stainless steel eye bolts running through the 2×8 rim joist. We also added windows to the doors (along with more internal framing for them) and a side window. The doors weighed a TON when we got them done, but they look great. Six 8″ heavy duty strap hinges handle the doors just fine. I used a locking t-handle system on the right door along with a spring bolt on top of the left door and a foot bolt at the bottom of the left door. The five foot wide, ¾” thick ramp is underpinned with 4 supports as my son-in-law intends to one day put a 4-wheeler in the shed.