SHOP BY STYLES

Backyard Shed Plans Barn Shed Plans Chicken Coop Plans Compost bin Plans Corner Shed Plans Detached Garage Plans Dog Kennel Plans Dormer Shed Plans Firewood Shed Plans Garage Shed Plans Garden Shed Plans Generator Shed Plans Greenhouse Shed Plans Hip Roof Shed Plans Horse Barn Plans Large Shed Plans Lean To Shed Plans Loft Shed Plans Low Income Housing Plans Metric Garden Sheds Modern Shed Plans Porch Shed Plans Run In Shed Plans Saltbox Shed Plans School Bus Shelter She Shed Plans Short Shed Plans Tiny House PlansSHOP SIZES

4x8 Shed Plans 4x10 Shed Plans 4x12 Shed Plans 6x6 Shed Plans 6x8 Shed Plans 6x10 Shed Plans 6x12 Shed Plans 8x8 Shed Plans 8x10 Shed Plans 8x12 Shed Plans 8x14 Shed Plans 8x16 Shed Plans 8x20 Shed Plans 10x10 Shed Plans 10x12 Shed Plans 10x14 Shed Plans 10x16 Shed Plans 10x18 Shed Plans 10x20 Shed Plans 10x24 Shed Plans 12x12 Shed Plans 12x14 Shed Plans 12x16 Shed Plans 12x18 Shed Plans 12x20 Shed Plans 12x24 Shed Plans 14x14 Shed Plans 14x16 Shed Plans 14x20 Shed Plans 14x24 Shed Plans 16x16 Shed Plans 16x20 Shed Plans 16x24 Shed Plans 24x24 Garage PlansSHED BUILDING VIDEOS

All Shed Building Videos Backyard Gable Shed Videos Lean To Shed VideosSHED IMPROVEMENT HOW TOO'S

Learn about Concrete, Electrical, Framing, Codes, Roofing, Solar and more!MORE SHED PAGES

Lean To Shed Ideas Office Shed Convert Shed Design Building A Shed How To Build A Home Shed Door Plans Build A Shed Ramp Eagle Scout Shed PlansHow To Build A Deck

Building a deck is a wonderful way to add living space to your home. A deck will provide an outdoor area for friends and family to gather or to simply spend quiet time in your yard. This article is intended to provide suggestions to help you design and build your deck, every deck and its construction is different. These deck building instructions will describe a square deck that has one of its 4 sides attached to a house. The deck building techniques are common to most decks. Always consult with your local city or county building department to find out about any codes or regulations that would affect your deck building project. Often the Plans Examiner or Building Inspector will have recommendations that may help you build your deck. It is advisable to consult a structural engineer, especially for large decks or when the deck is carrying loads such as large amounts of people or hot tubs etc.

brief how to

- Parts of A Deck

- Install The Deck Joist Ledger

- Layout The Joist Locations On The Ledger

- Layout The Deck Footings

- Dig The Deck Footings

- Install Post Bases

- Mix and Pour The Concrete

- Attach The Post Bases

- Install The Deck Beam Posts

- Set The Posts On The Footing And Under The Beam

- Layout The Joist Location On The Ledger And Beam

- Attach The Joist Hangers

- Set The Joists In Their Hangers

- Install The Railing Posts

- Install The Decking Boards

- How To Build Deck Stairs

tools and materials

- Circular saw

- Tape Measure

- Pencil

- Screw gun with the proper tip to screw in the screws you purchased

- Speed Square

- Screws and Nails

- Post Caps and Post Bases

- Deck lumber per plans

- 40 lb. bags of pre mixed cement

step 1 Parts Of A Deck

step 2 Install The Deck Ledger

A ledger is used to attach the deck to a house, it is the piece of lumber that is screwed to the house and the deck joists hang on. Once the ledger is installed it will be used as a reference to build the rest of the deck so it is the first part to be installed.

Layout: Layout of the ledger is done by figuring out where it will be positioned on the wall and drawing an outline of it on the wall. Determine whether it is necessary to remove the siding from your house under the ledger and add flashing or if you can bolt the ledger directly to the siding.

Flashing: The connection point of the deck to the house is very vulnerable to water problems because the deck has the potential to hold water on top of it and if that water flows toward the house it needs to be kept outside. There are several precautions you need to take to keep the water outside. If done right you should have no problem. You will need two pieces of flashing: One to go over the top of the ledger and one to go behind the ledger and down and over the siding and or foundation below the ledger. If you are removing the existing siding be sure to install a “Z" flashing under the siding and over the top of the ledger to keep water from running behind the ledger. The place where you buy your lumber will help you find the size to fit your ledger.

Determine the distance below the floor level by adding together the following:

- 6 1/2" open space to avoid water from running from the deck into the home.

- The thickness of your decking material. (usually 1 1/2 inches).

This is the top of your joist ledger. (usually 8 inches below the door threshold)

Mark The Ledger Location: Mark the elevation of the top of the ledger so you can easily see it. Determine the length of it and mark each end. Draw a line the full length of it with a chalk line or a level and a pencil.

Ledger Length: The end joists will go on the ends of the deck so the ledger will need to be shortened so the end joist can lap over the ledger. Cut your ledger to the length of your deck minus the thickness of the joist at each end, usually 3 inches if your joists are 1 1/2" thick, and attach it to the wall. The end joists are attached to the end of the ledger, the joists in between are attached using joist hangers.

tip: if the bottom of the deck joists are within a few inches of the top of the foundation make sure that the flashing coming from the back side of the ledger board goes over the face of the foundation so the water will run onto the face of the foundation and not behind it. This also helps with water drainage off the house.

Attach The Ledger: Attach the ledger with lag screws and washers. Make sure that the screws go into the vertical wall studs on the house. It is typical to use 2 screws every 16". Place them about 2" from the top and bottom of the ledger. Drill holes in the ledger to make it easier to drive the screws. The screws should be long enough to penetrate the wall studs about 3", so if your ledger is 1 1/2" and the siding 1/2" you will need to use 5" lag screws.

step 3 Layout The Joist Locations On The Ledger

Layout the joist hanger locations on the ledger by putting a mark where each joist will go. Most decks have a joist layout of 16 inches on center but sometimes the joists can be laid out at 12 inches on center or 19.2 inches on center. Remember that the ledger is 1-1/2" shorter on each end to account for the joist that will be there so overhand your tape measure 1-1/2" when marking the layout. See our Layout page for detailed instructions.

step 4 Install The End And Rim Joists

Install the End Joists: Start at one of the ledger ends and install the first joist of the deck by nailing the end joist to the deck. The ledger was cut short on each end to accommodate the thickness of this first joist. After nailing the joist to the end of the ledger make sure the joist is level and eyeball its closeness to being square with the ledger as possible then nail a temporary board to the side of the joist to hold it, nail an angled board from the joist to the ground to keep the whole thing from falling over. The angled braces should be strong enough to resist movement when you bump into the deck. If you are in doubt, install another brace. Next install the other end joist at the opposite end of the ledger and brace it like you did the first end joist.

Install the Rim Joist and support and brace as needed: Now install the "rim" joist at the end of the deck. It will be 3 inches longer than the ledger because the rim joist overlaps ends of the end joists. Nail the rim joist to the two ends of the end joists that you already installed. It is a good idea to put a brace from the center of the rim joist to the ground.

Check the joists for “square" by cross measuring from corner to opposite corner, when the measurement is the same then your deck is square. (see drawing)

step 5 Layout The Deck Footings

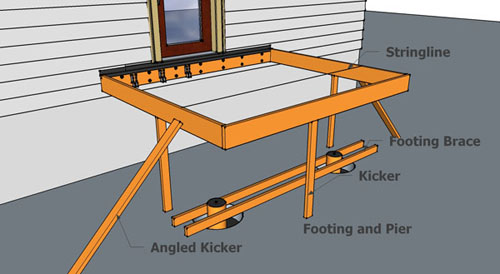

The easiest way to layout the footings for your deck, especially if you have angles on the deck or a sloping lot, is to build the outer perimeter of the deck first and locate the footings from the perimeter boards.

Layout The Beam Locations: Decks typically have a beam to hold all the joists above the ground. Every deck is different so check your plans to make sure the beam size and location are correct. Measure the proper distance from the house and mark the center of your beam on the end joists. This mark will be the center of your footing.

Layout The Footing And Concrete Pier Locations: Now that you know where the deck beam goes you can locate the footings that will hold the beam. Pull a string line between the two beam marks. Check your plans to see the exact location of the footing and post. Use a permanent marker to mark the string where the center of the footing and pier will go. Use a level or plumb bob to go from the mark on the string to the ground, this is the center of the footing and pier. Mark the center of the footing on the ground and then measure out from that to the edges of your footing hole. Now you are ready to dig the footing holes.

Layout The Stair Landing: The stair landing may be poured when the footings are poured so you may want to locate them now and form it so it is ready to pour when the concrete is mixed for the footings. Read the article How To Pour A Concrete Pad Or Landing to learn how to make a concrete pad.

step 6 Dig The Deck Footings

The deck footings are the "feet" of the deck because a footing is what the deck stands on. Footings are made from concrete and poured in place.

Dig The Footing Holes: Dig a minimum of 12 inch round or 12 inch by 12 inch square hole for each deck footing. The holes must be deep enough so the bottom of the footing is below the frost line in your region. Digging the hole 6" deeper than the frost line and filling it with 6" of gravel before installing the concrete is recommended to give the footing better drainage, but may not be necessary if the soil in your area has good drainage. It is recommended to dig deep enough to allow for 6" of top soil on top of the footing to allow grass to grow.

step 7 Install the Pier Forms:

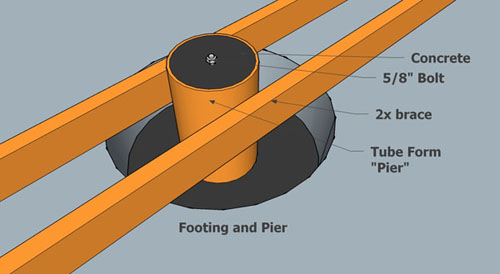

This pier and footing installation method installs the pier and footing at the same time. You will install the cardboard concrete pier forming tube over the hole before the footing is poured. If you are not comfortable pouring the pier and footing all at once you can pour the footings first and after the concrete hardens you can come back and pour the pier.

Install The Pier Forms: After the hole is dug and gravel installed, hang a 8" or larger cardboard concrete forming tube in the footing hole. The bottom of the tube will be hanging above the bottom of the footing by 10 inches. To hold it off the ground use 2-2x6 boards and nail or screw through the board into the side of the tube (see drawing). The top of the tube should be six inches above the finished grade (grass, dirt or other material in your yard) and 10 inches above the bottom of the footing hole.

"Measure twice and build it once". Check everything again for square and proper heights before mixing the concrete.

step 8 Mix And Pour The Concrete

Concrete can be purchased in 80 pound bags from a home store or pre-mixed by a local company and delivered by truck to your home. The easiest system to pour concrete when you build deck footings involves a truck that mixes the concrete on site. These trucks can mix only the amount you need so they are usually more cost effective for small projects like building deck footings.

Mix The Concrete: Mix the concrete so that it is thicker like oatmeal. Pour the footings first and let them set up for a few minutes and then fill the pier tubes to the top. If the concrete settles in the pier tube then the mixture has too much water, you may need to let it set up a bit and then top off the pier tube. You don't need to smooth the top of the footing but you will need to smooth the top of the posts as this will be visible when the cardboard is removed. Tap the sides of the tube to remove air holes where the cardboard meets the concrete. This may settle the concrete on the top of the tube, just add a little more to the top.

Amount Of Concrete Mix: Use the mixing instructions on the bag to determine the amount of mix to use for your hole size. A 12" x 12" wide by 12" deep hole requires 1 cubic foot. It takes about one and two thirds of 80 lb bags of concrete to make 1 cubic foot of concrete.

step 9 Install Post Bases

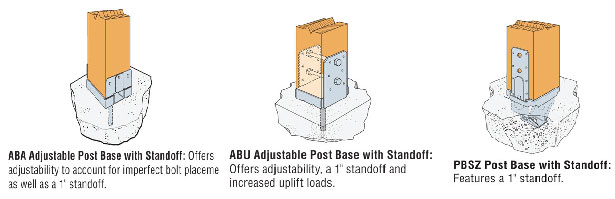

Post bases are metal connectors that hold the wood post holding the deck beam to the concrete pier or slab. The two types of anchoring include installing the anchor during the concrete pour or after the concrete hardens.

Post Base Install During The Pour: The simplest type of post base to use is one that has the 5/8" anchor bolt seperate from the post base. The anchor bolt is set in the concrete when the concrete is wet and then the post base is bolted onto the anchor bolt after the concrete hardens. The "adjustable" post bases have about 1 inch of play to allow a little bit of imperfect bolt placement. Use a string line pulled between the tops of the cardboard pier forming tubes to locate the anchor bolts when the concrete is wet. Make sure the bolt is no more than 3/4" above the top of the finished concrete.

Post Base Install After The Concrete Hardens: Installing the post base after the concrete hardens is done by drilling a hole in the concrete and anchoring the bolt in the hole with epoxy. (epoxy is sold where you purchase the post base).

Note: Simpson makes post bases designated AB for “Adjustable Base" which allow a lot of room for error, over 1 inch of play. If you are not comfortable with placing it by hand you may build a jig from a small piece of wood laid across the top of the tube. Drill a hole in it and install the bolt thru the hole, letting the bottom of the bolt hang down into the top of the tube. Either way make sure the top of the bolt is no more than 3/4" above the top of the finished level of the concrete. It is not recommended to drill in the anchor bolts after the concrete pier has hardened because drilling on a small surface area like a concrete pier may crack the concrete.

Bolt On The Post Base: After the concrete hardens attach the Post base on the 5/8" bolt. Make sure it is square with the beam direction and tighten the nut down.

step 10 Install The Posts On The Pier And Under The Beam

After the concrete hardens and your post bases are set you are ready to cut the posts to the proper length.

Measure And Cut The Wood Posts: Move the string line that was used to mark the center of the beam to the edge of the beam and posts location, usually about 1 1/2". Do this at both ends so it remains parallel to the ledger on the house. Make sure the joists are still level and square with the ledger. Stand your post in the post base. Make sure it is plumb and just touching the string line. Mark the post where the string line hits it. Subtract the depth of the joist and the depth of the beam from the string mark on the post and cut the post to this length.

Install The Post Caps: Post caps are used to connect the top of the wood post to the wood beam. Use the fasteners that are recommended by the manufacturer. The joists should now be resting on the beam and not the temporary vertical braces. Keep the angled braces in place to prevent the deck from moving from side to side. Note, these are called lateral braces.

step 11 Layout The Joist Location On The Beam

Mark The Beam: Layout the beam where the joists will rest on it. Make sure they match the ledger layout. Any time you build a deck you should always layout from the same side of the structure with the same spacing.

Mark The Rim Joist: Layout the joist locations on the rim joist for each joist.

step 12 Attach The Joist Hangers

Joist Hangers: Attach the joist hangers to the ledger on the layout marks. Make sure you do it on the correct side of the mark. When nailing a joist hanger on it is a good idea to use a piece of the joist that will be used to make sure that the hanger is set at the proper height and the opening is wide enough to fit the joist.

Angled Clips: Use angled clips to attach the joists to the beam, you can attach these to the beam before attaching the joist. Verify that you have the proper nail for your situation. A worker at the pro desk of your local hardware store can help you interpret the hanger catalog to pick the right nails.

step 13 Set The Joists In Their Hangers

Measure The Joist Length: Measure the distance between the rim joist and the ledger. Cut each joist to length and install it in its hanger and attach it to the beam.

Crown The Joists: Crown the joist by looking down the edge and putting the edge that bows up, up.

Set The Joists: Set the joists in their hangers on the ledger and on the mark or clips on the beam. Nail each one before moving to the next one. It is hard to nail on a joist when another one is next to it. Install blocking if it is required by local building codes. This is also hard to do after the decking is on. Nail the rim joist to the joists. Make sure that the rim joist does not bow out or in, you can pull a string line down the rim joist to verify that it is straight.

step14 Install The Railing Posts

The most common, and strongest way, to build the deck railing is to attach the railing posts to the side of the joists. The posts will need to be attached before the decking material is installed. This step describes how to build a handrail on a deck. Read the article Deck Handrail Designs for ideas. Railings are required to be 42 inches high and have no more than a 4 inch sphere

Start At The Corners: Install a post at each corner of the deck. The post will pass thru the decking material and attach to the side of the joist. Attach the post using a

Some deck designs attach the railing posts to the top of the decking material but that is not as strong as running the post thru the decking and down the side of the joists.

Be sure to install blocking around the post at the level of the top of the joists so the decking can rest on it. Install the corner posts and stair posts first then evenly space the posts between. Verify the maximum distance between posts with local building codes.

step 15 Install The Deck Boards

Your are now ready to install the decking on your deck!

Start at the deck edge: Start by installing the first board at the outer edge of the deck and work towards the house. The decking boards always run perpendicular to the joist direction. Cut the deck boards so they land exactly on the center of a joist. You can let the ends of the decking hang over the edge of the deck and cut them all at once to make a nice straight line.

Spacing the joints: Spacing between boards is determined by the decking material. Man made products have different requirements than woods like pressure treated wood, hardwoods and redwood. If you are using a product that shrinks you can butt the edges up to each other if you are using a non shrink product you can put a 1/8" joint between the deck boards by using several nails in the joint when laying each board.

- Make sure that any end, “butt", joints are centered over a joist.

- Do not put spacing between the butt joints, only space between the side joints.

- Stagger the butt joints so they are not all on one joist, this weakens the deck and looks bad.

- Cut the ends off the boards after you have them all screwed down. Snap a chalk line and cut them all at once. This saves time and creates a nice straight edge on your deck.

Finish at the house wall: Hold the board 1/8" off the wall to allow for drainage and air flow.

Fastening: Fastening the decking is best done with deck screws. Nails tend to work their way out of the wood and pose a tripping hazard. All screws and nails on the deck must be hot dipped galvanized, or stainless steel or aluminum. Use two screws per board on deck material up to 6" wide and 3 screws for wider deck boards. Decking screws have small heads that allow them to go under the surface of the deck wood to keep them out of harms way.

step 16 How To Build The Deck Stairs

If your deck needs stairs you will want to read the article How To Build Deck Stairs. This article has detailed information on building stairs for your deck or other project.

step 1 Figure Out Riser Height And Decide The Tread Depth

Stair stringers, are the part of the stairway that holds the stair treads. The first step in building stairs is to find the floor to floor height. This is done by measuring from the top of upper floor to the top of lower floor. Convert this number to inches, then divide the floor to floor height by 7.5, round up to the next whole number, divide the floor to floor height by the whole number, this is your stair riser height.

for example: floor to floor height is 4'-6"

- Convert the total height to inches 4 x 12 = 48" plus the 6" is 54"

- divide 54" / 7.5 = 7.2 (7.5 inches is the optimal riser height so you start there and get a number that is close.)

- round up to 8 this is the number of risers you will have.

- divide 54 by 8 = 6.75

- convert 6.75 to inches, 6 3/4" rise

If you have access to a construction calculator, there are several stair calculators on the internet,

another method is to simply divide the number of estimated risers into the floor to floor height until you get a number at or below 7 3/4"

To figure the tread depth it is easiest to use a 10 inch rough cut for the tread will allow you to use 2 - 5 1/2" boards side by side plus the gap between boards makes 11 1/8" total tread. Verify your landing distance from the deck.

step 2 Draw The Cut Lines On The First Stringer

step 3 Cut Out The Rise And Runs

After cutting it out, hold it up to the deck at the height it will be mounted, remember to have it lower by the thickness of the tread that goes on top of it.

step 4 Draw The Cut Lines On The Other Stringers

step 5 Cut Out The Rise And Run

step 6 Cut the thickness of one tread off the bottom of the stringer

step 7 Install the stringer hanger(s)

step 8 Install the first stringer

Deck Stair Codes: There are rules relating to the construction of stairs that hopefully keep them safe for users. Above are a few of the codes required by most building inspectors. Check with your local building department for requirements specific to your area. Check out this graphic that shows the basic codes for building a deck stair handrail.